The difference between closed cell foam and open cell foam

Written by The Foam Factory

Written by The Foam Factory

Most foam manufacturers will manufacture both open and closed cell foams. Since the characteristics of both these products are different, the type of foam you should use will depend on the application or desired outcome.

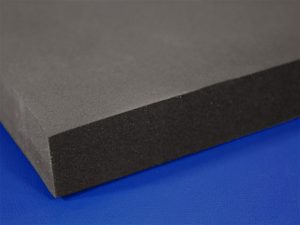

With many vendors online selling closed cell foam Canada and around the US, this product has become readily available in the market. Closed cell foams have gas bubbles and are permanently locked into place, during the manufacturing process of the foam. This creates a product that provides better insulation and one that is strong. Since these are high-density foam sheets they are resistant to liquid water and therefore very durable and can last throughout the life of a property. Choose to use this form of sheeting in both interior and exterior environments. Due to the sheets strength, they can be used to increase structural strength.

Open cell foams, on the other hand, are very different. The cells on these sheets have air and function more like a sponge. Since these foams are porous, they do not resist water or humidity. The manufacturing process creates low-density foam sheets, making them less durable than closed cell foam sheets. Consider using this form of sheeting for interiors that require sound deading.

The sheeting you choose will greatly depend on your end use. Make sure you purchase your sheets from a reputed vendor that will advise you on the best type sheets for your use.

_______________________________________________________________

The Foam Factory specializes in foam products suitable for packaging foam Canada.